The worm gear slewing drive for construction machinery is a specialized reduction device that integrates a worm gear transmission and a slewing bearing structure. Its core function is to convert the high speed and low torque of the driving motor into low speed and high torque, enabling smooth and precise rotation of the construction machinery's slewing mechanism.

WE Series Worm gear type Slew Drive Reducers 5 inch 9inch 15 inch 40 inch for Construction Machinery

Product Description

Customization

Product Introduction

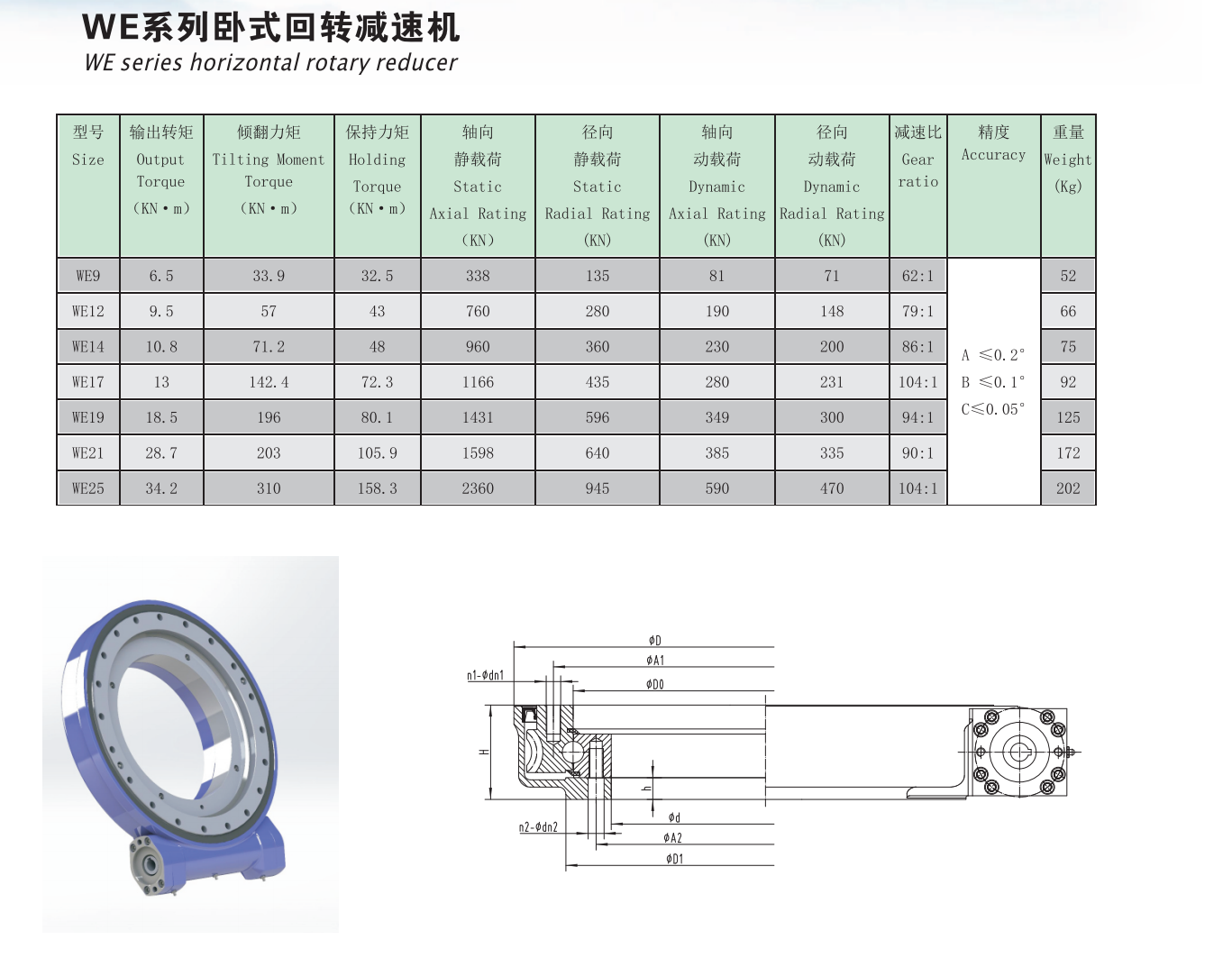

Specifications / Parameters

| Product Name | Material | Dimensions | Style |

| Slew Drive Reducer | 42CrMo | 5 inches / 7 inches / 9 inches | Yellow / Black/Blue/Every colour |

Specifications / Parameters

It mainly has three core characteristics:

Compact structure + high integration: Usually integrated with the slewing bearing, it has a small volume and is easy to install, adapting to the limited installation space of construction machinery, while simplifying the overall transmission chain.

Large transmission ratio + high torque: The worm gear meshing structure can achieve a large speed reduction ratio in a single stage, providing strong output torque to meet the heavy-duty slewing requirements of equipment such as excavators, cranes, and aerial work platforms.

Good self-locking performance: Most worm gear drives have a reverse self-locking function, which prevents the equipment from reversing due to its own weight or load, improving operational safety.

FAQ

-

When can the "Fangyuan" brand be traced back to?

Production of internationally advanced "Fangyuan" brand slewing bearings began in 1984. -

What are the main application areas of your products?

Our products are widely used in engineering equipment machinery, solar photovoltaic, solar thermal new energy, and intelligent equipment fields. -

What certifications has the company obtained?

The company has obtained ISO9001:2015 quality management system certification, ISO45001:2018 occupational health and safety management system certification, and ISO14001:2015 environmental management system certification. -

What equipment does the company possess?

The company possesses over 200 sets of advanced domestic production and testing equipment, including life testing machines, vertical and horizontal rotary reducer torque testing benches, sealing performance testing benches, rain test chambers, dust test chambers, salt spray test chambers, and condensation test chambers. -

What is the approximate product delivery time?

Sample production typically takes around 40 days; delivery speed increases after mass production begins. -

What is the company's maximum annual production capacity?

We can produce 50,000 rotary gear reducers for construction machinery and 400,000 rotary gear reducers for photovoltaic applications annually. -

What types of products does the company generally offer?

Photovoltaic rotary gear reducers are divided into two main categories: mechanically linked and electrically linked. Construction machinery rotary gear reducers are divided into three main categories: helical gear, worm gear, and vertical/horizontal combination type. -

Contact Information

For international business, please contact Crystal: +86 18856562276 (WeChat/WhatsApp) crystal@fycdkj.cn For domestic business in China, please contact Feng Fei: +86 15905558586 fengfei@fycdkj.cn